Introduction

Based on General Motors’ ‘Generation IV’ architecture, the LS7 was a 7.0-litre pushrod V8 petrol engine that was a road-going version of the engine that powered Chevrolet’s Corvette C6.R Le Mans race car. Hand-built at GM Performance Build Center in Wixom, Michigan, the LS7 engine was first deployed in the Chevrolet Corvette Z06. For Australia, the LS7 engine was solely available in HSV’s limited-run E-Series W427 which was produced from 2008 to 2009.

LS7 block

The LS7 engine had a deep-skirt, cast aluminium block which underwent a deck plate honing process typically reserved for racing engines. With its 104.775 mm bores and 101.6 mm stroke, the LS7 engine had a capacity of 7008 cc. Due to its 111.76 mm bore spaces, the LS7 engine required pressed-in cylinder liners. Furthermore, the LS7 engine weighed 208 kg.

LS7 internals

The LS7 engine had a precision-balanced forged steel crankshaft, titanium connecting rods that weighed 480 grams each and hypereutectic aluminium pistons; the crankshaft was supported by five main bearings each of which had six CNC-machined forged steel main bearing caps (four vertical and two horizontal). As a result of its internals, maximum engine speed for the LS7 was 7000 rpm, 400 mm higher than the LS3.

LS7 cylinder head

The LS7 engine had CNC-ported aluminium cylinder heads which provided 25 per cent more airflow than the LS2. Furthermore, LS7’s valve angles were 12 degrees (compared to 15 degrees for the LS2) for improved airflow through the ports.

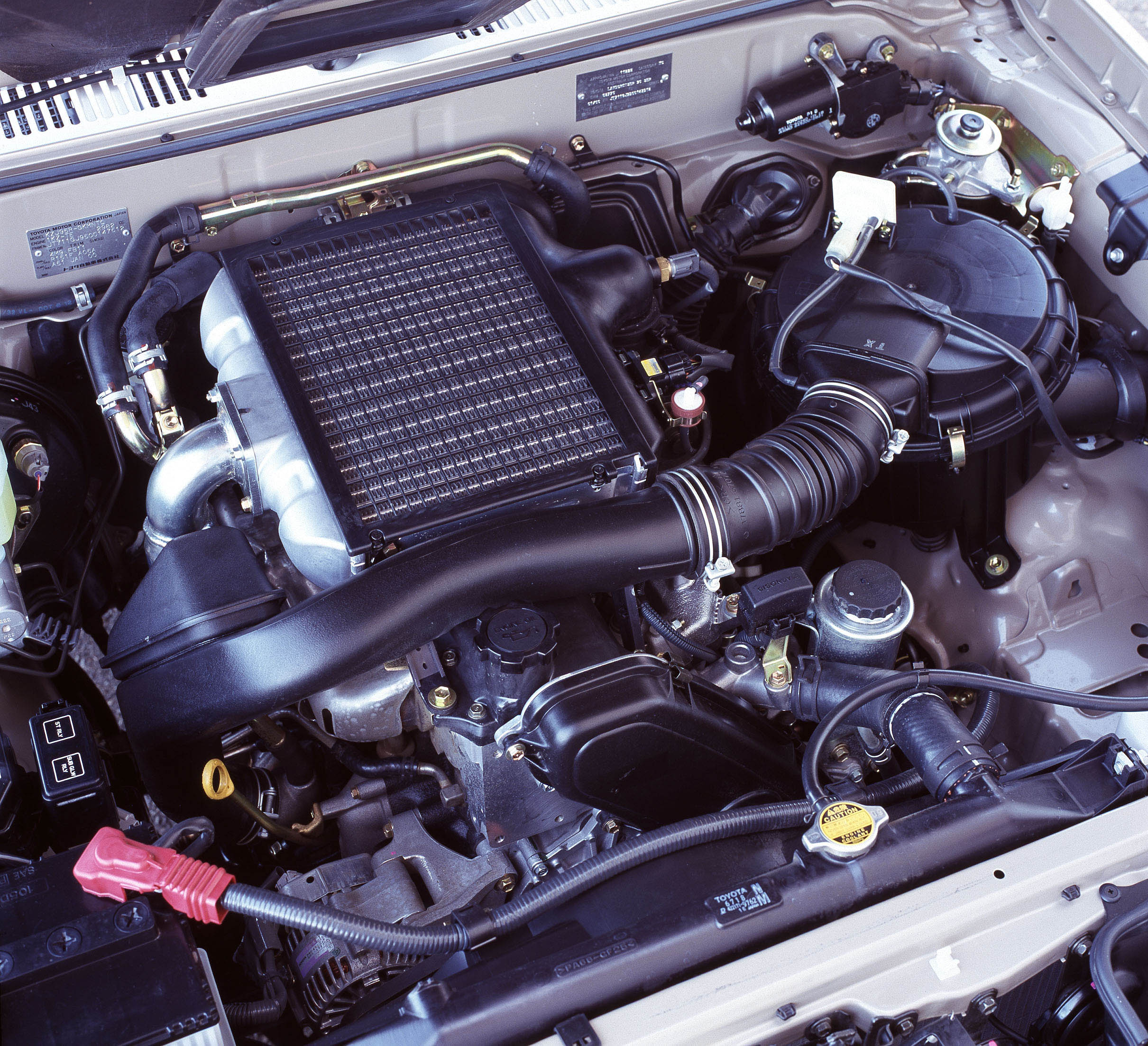

Like other Gen IV engines, the LS7 had a composite, three-piece friction-welded intake manifold. For the W427, the dry sump lubrication system meant that an over-radiator cold air induction system needed to be developed.

LS7 camshaft and valvetrain

The LS7 had a single, hollow camshaft that was produced from steel billet and had induction-hardened lobes. The camshaft provided 15 mm of lift for the intake and exhaust valves, while the roller rocker arms were offset on the intake side and had a 1.8:1 ratio.

The LS7 engine had 56 mm (diameter) titanium intake valves that were supplied by Del West and 41 mm sodium-filled exhaust valves. For the LS7, the valves also had raised spring seats.

LS7 lubrication

The LS7 had a dry sump lubrication system, a two-stage oil pump, a front-mounted thirteen row oil cooler and an oil catch can.

LS7 injection and ignition

The LS7 engine had electronic, sequential port fuel injection (SFI) and each cylinder had its own injector to meter fuel – for the LS7, the high capacity injectors could supply five grams of fuel per second. Each cylinder had its own ignition coil, coil driver assembly and short plug wire that connected to the spark plug.

The LS7 had a compression ratio of 11.0:1.

W427 exhaust

The W427 had ceramic-coated headers, four-into-one extractors, high-flow catalytic converters and stainless steel exhaust pipes (2 3/4-inch aft of the catalytic converters). The bi-modal muffler was electronically-controlled.

| RPO | Engine | Peak power | Peak torque | Models | Years |

|---|---|---|---|---|---|

| LS7 | 7.0-litre petrol V8 | 375kW at 6500rpm | 640Nm at 5000rpm | HSV E-Series W427 | 2008-09 |