Introduction

The 1LR-GUE was a 4.8-litre V10 petrol engine that powered the Lexus LFA. Co-developed with Yamaha, the 1LR-GUE produced peak outputs of 412 kW at 8700 rpm and 480 Nm at 7000 rpm. Furthermore, maximum engine speed was 9000 rpm and 90 per cent of peak torque was available from 3700 rpm to 9000 rpm. The 1LR-GUE engine could rev from idle to 9000 rpm in 0.6 seconds, such that a digital LCD tachometer was used to match the engine’s ability to vary revolutions.

The 1LR-GUE engine also featured dry sump lubrication for lubrication capable of withstanding sustained high-speed cornering in excess of 2g.

| Engine | Trans. | Years | Peak power | Peak torque | |

|---|---|---|---|---|---|

| Lexus LFA | 1.8-litre petrol I4 (7A-FE) |

5sp man., 4sp auto |

1994-99 | 85kW at 5600rpm | 155Nm at 2800rpm |

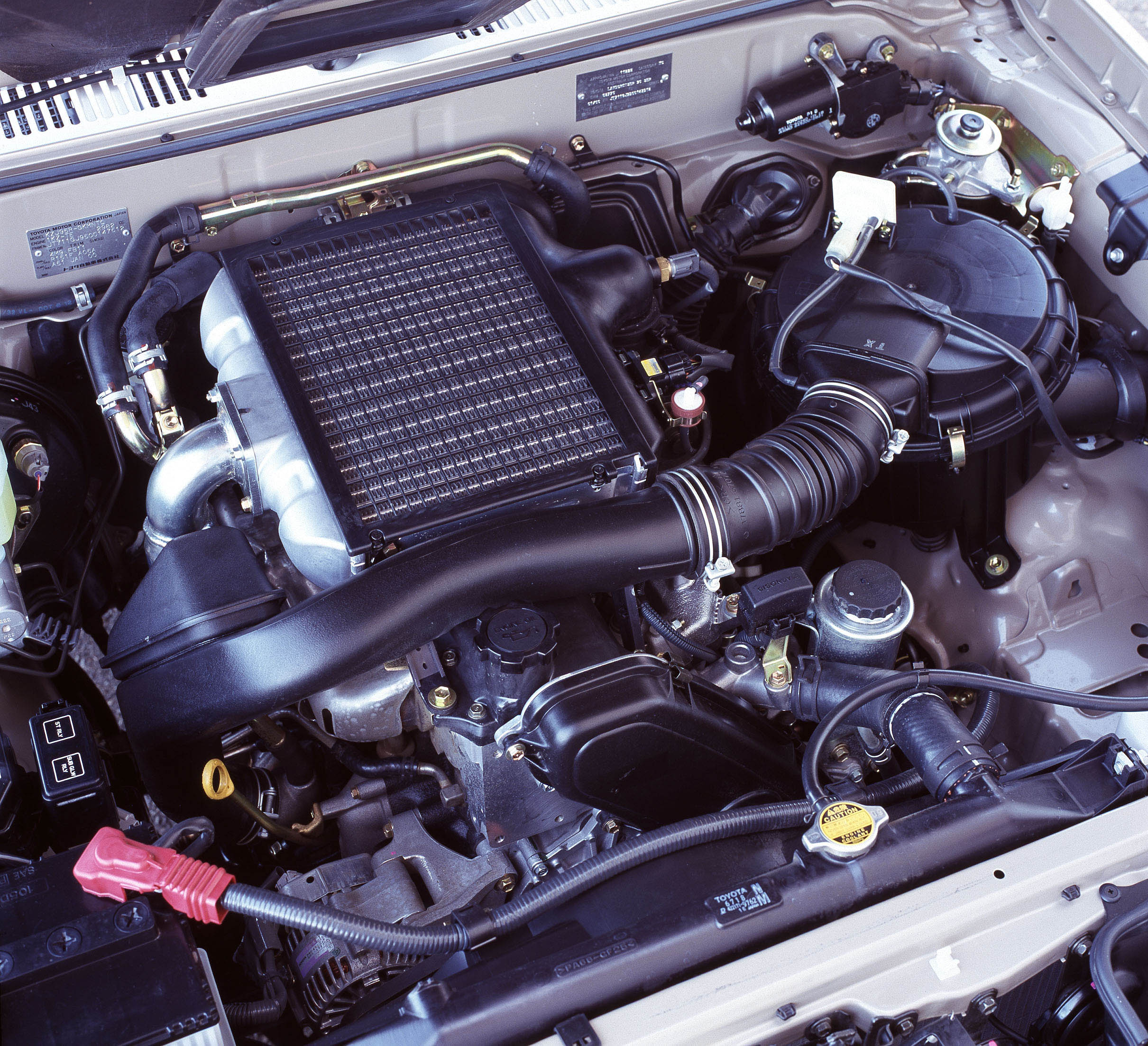

1LR-GUE block and internals

The 1LR-GUE had an aluminium alloy block with 88.0 mm bores and a 79.0 mm stroke for a capacity of 4805 cc. The cylinder banks had a 72 degree ‘V’ angle for balancing the primary and secondary movement of the internals, and to circumvent the need for a split-journal crankshaft.

The 1LR-GUE engine had forged titanium alloy connecting rods, which were 40 per cent lighter than equivalent iron components, and forged aluminium pistons.

Cylinder head

The 1LR-GUE engine had an aluminium alloy cylinder head with double overhead camshafts and dual ‘Variable Valve Timing – intelligence’ (VVT-i). Furthermore, the 1LR-GUE engine had a magnesium alloy cylinder head cover.

Valves

The 1LR-GUE engine had four solid titanium valves per cylinder: two intake and two exhaust. The valves were actuated by solid rocker arms which were produced from high-strength tool steel and had a narrow profile for mass reduction. To reduce friction, the rocker arms had a diamond-like carbon/silicon coating.

Significantly, the valvetrain for the 1LR-GUE engine was estimated to have around half the inertia mass of a conventional high-performance engine that used steel valves and bucket type valve lifters.

Intake and throttle

The 1LR-GUE engine had a dual intake system that could switch from a primary inlet port at low to medium engine speeds to dual ports at higher speeds to enhance breathing efficiency.

Each cylinder had an independent, electronically controlled throttle body and throttle response was optimised by adopting ‘prioritised logic functionality’, which estimated air volume based on throttle pedal angle and enabled the appropriate injection volume to be calculated faster than a conventional system.

Injection and ignition

The 1LR-GUE engine had electronic fuel injection and twelve-hole injectors. For ignition, the 1LR-GUE had PK22HTBR-L8 Denso spark plugs, while the compression ratio was 12.0:1.

Exhaust and emissions

The 1LR-GUE engine had separate, equal-length exhaust manifold runners. Harmonic management used at the titanium dual stage rear silencer which incorporated a valve-actuated structure to vary exhaust sound. At engine speeds beyond 3000 rpm, all sound-deadening chambers were bypassed.

To reduce emissions, the 1LR-GUE engine had an air injection system which included an air pump that supplied fresh air into the exhaust after cold-engine start and early activating catalytic converters.